Capacity

Swing over bed mm (inch) 230 (9.1)

Swing over saddle mm (inch) 230 (9.1)

Recom. Turning diameter mm (inch) 210 (8.3)

Max. Turning diameter mm (inch) Upper turret : 230 (9.1) / Lower turret :230 (9.1)

Max. Turning length mm (inch) 230 (9.1)

Chuck size(Left spindle) inch 8 / 8

Bar working diameter mm (inch) 65 / 65 (2.6 / 2.6)

Travel

Travel distance

X1/X2-axis mm (inch) 165 (6.5)

Z1/X2-axis mm (inch) 700 (27.6)

Y-axis mm (inch) 100(±50) (3.9(±2.0))

A-axis mm (inch) 730 (28.7

Feedrates

Rapid Traverse Rate

X1/X2-axis m/min (ipm) 30 (1181.1)

Z1/X2-axis m/min (ipm) 40 (1574.8)

Y-axis m/min (ipm) 15 (590.6) 15 (590.6)

A-axis m/min (ipm) 40 (1574.8)

Left spindle

Max. Spindle speed r/min 5000

Max. Spindle power kW (Hp) 25 / 18.5 / 15 (44.9 / 24.8/ 20.1) (S3 25% /S3 60% /Cont.)

Max. Spindle torque N·m (ft-lbs) 223 (164.6)

Spindle nose ASA A2 #6

Spindle bearing diameter (Front) mm (inch) 110 (4.3)

Spindle through hole mm (inch) 76 (3.0)

Min. spindle Indexing angle(C-axis) deg 0.001

Right spindle

Max. Spindle speed r/min 5000

Max. Spindle power kW (Hp) 25 / 18.5 / 15 (44.9 / 24.8 / 20.1) (S3 25% / S3 60% / Cont.)

Max. Spindle torque N·m (ft-lbs) 223 (164.6)

Spindle nose ASA A2 #6

Spindle bearing diameter (Front) mm (inch) 110 (4.3)

Spindle through hole mm (inch) 76 (3.0)

Min. spindle Indexing angle(C-axis) deg 0.001

Turret

No. of tool stations (Upper+Lower) ea 24 +24 position 24 +24 position

Holder mount type - BMT55P

OD tool size mm (inch) 20 x 20 (0.8 x 0.8)

Max. boring bar size (Main/Sub) mm (inch) Ø32 (Ø1.3)

Turret Indexing time (1 station swivel) s 0.12

Max. Rotary tool speed r/min 5000

Max. Rotary tool speed power kW (Hp) 7.5 / 1.1 (10.1 / 1.5)(S2 5min / Cont)

Max. Rotary tool speed torque N·m (ft-lbs) 47.7 (35.2)

Power source

Electric power supply(rated capacity) kVA 75.21

Machine Dimensions

Length mm (inch) 3880 (152.8)

Width mm (inch) 2360 (92.9)

Height mm (inch) 2250 (88.6)

Weight kg (lb) 10000 (22045.9)

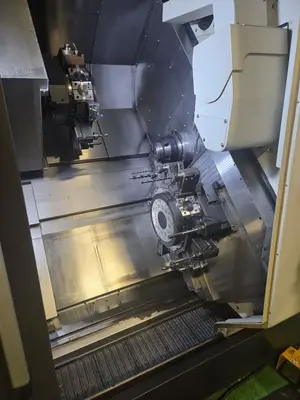

Fanuc Oitf Cnc Control

Doosan Ez Guide I Programming

Twin 12 Position Turrets Upper And Lower, W/24 Position Indexing On Each Turret With Base Mount Tooling System

Y-axis On Both Turrets

(2) Integral Spindles

Full Contouring C-axes On Both Spindle

Mill/drill On Upper And Lower Turrets

Parts Catcher Left And Right

Programmable Parts Unloader

Parts Conveyor

(2) X-axis Live Holders

(2) Z-axis Live Holders

Standard Factory Static Tooling

Doosan Tool Load Monitoring System

Air Blast System For Chuck Cleaning

*Specifications Subject to Buyer Verification.

We use cookies to improve your experience. Privacy Policy.